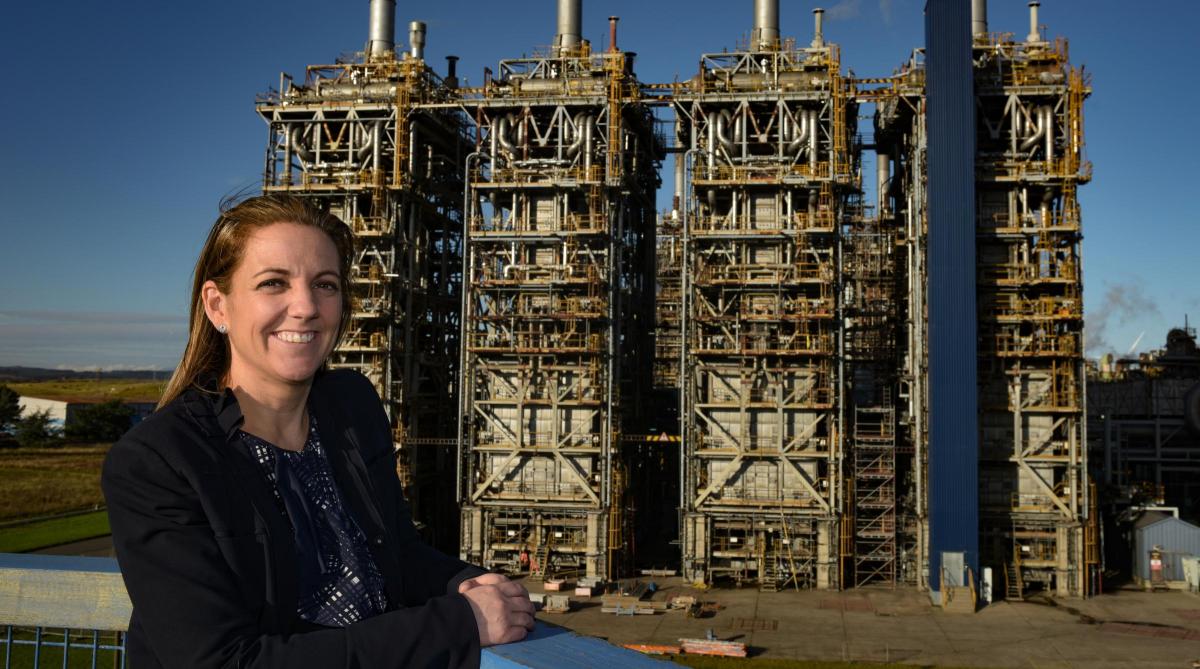

BOSSES at the Fife Ethylene Plant are "totally committed" to reducing flaring at Mossmorran as they pride themselves on being a "good neighbour".

The plant run by ExxonMobil Chemical Ltd has been investigated by the Scottish Environmental Protection Agency (SEPA) and the Health and Safety Executive (HSE) after flaring incidents at the facility in the past two years.

Sonia Bingham, plant manager, said: "We’re totally committed to minimising our flaring and particularly unplanned flaring. We know the concern and disturbance that it causes. We’re totally committed to reducing that occurrence, but obviously if it does occur, as it’s part of our system here, that we make sure we give that reassurance to the community that we’re doing everything we can to resolve it."

Final warning letters were served to both ExxonMobil and Shell UK Ltd in April after unplanned flaring at the site last June.

Further episodes of flaring also took place in October 2017, and then in March and May this year.

The flare is vital to ensuring the plant runs safely, and Ms Bingham added that the disturbances local residents have endured and complained about are taken seriously.

She said: "I think we’ve always prided ourselves as being a good neighbour and a member of the community here. Following on from the flaring we had in the last couple of years, getting the feedback from the people in the local community on their concerns, and also asking them what we can do better to improve things, gave us input into the actions that we needed to take.

“One of the resounding messages we got from the community was with regards to our communications. Most importantly, when we do have an unplanned incident when something is different to the norm. So one thing we’ve really focused on is how we can improve our base communication, and when there is an unplanned production issue we get our communications out on an increased frequency and in a format and language that people can readily understand."

It is in ExxonMobil's own best interests to cease flaring as quickly as possible, as the interruption in production results in a loss of business.

Gas from the North Sea is fed into the site before being heated in the plant's furnaces at a blistering heat of 750 degrees celcius.

Ethylene is produced (830,000 tonnes per year) and transported by ship to another facility where it is turned into Polyethylene, a solid plastic for sale.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here